| 1. |

Kang H, Zeng Y, Varghese S. Functionally graded multilayer scaffolds for in vivo osteochondral tissue engineering. Acta Biomater 2018; 78:365-77. doi: 10.1016/j.actbio.2018.07.039.

doi: 10.1016/j.actbio.2018.07.039

|

| 2. |

Nooeaid P, Salih V, Beier JP, et al. Osteochondral tissue engineering: scaffolds, stem cells and applications. J Cell Mol Med 2012; 16(10):2247-70. doi: 10.1111/j.1582-4934.2012.01571.x.

doi: 10.1111/j.1582-4934.2012.01571.x

|

| 3. |

Yang PJ, Temenoff JS. Engineering orthopedic tissue interfaces. Tissue Eng Part B Rev 2009; 15(2):127-41. doi: 10.1089/ten.teb.2008.0371.

doi: 10.1089/ten.teb.2008.0371

|

| 4. |

Hunziker EB. Articular cartilage repair: basic science and clinical progress. A review of the current status and prospects. Osteoarthritis Cartilage 2002; 10(6):432-63. doi: 10.1053/joca.2002.0801.

doi: 10.1053/joca.2002.0801

|

| 5. |

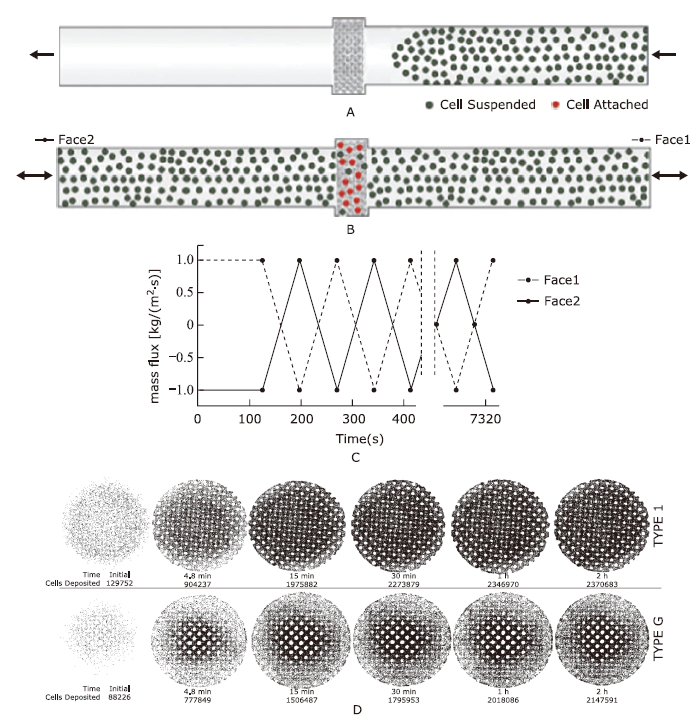

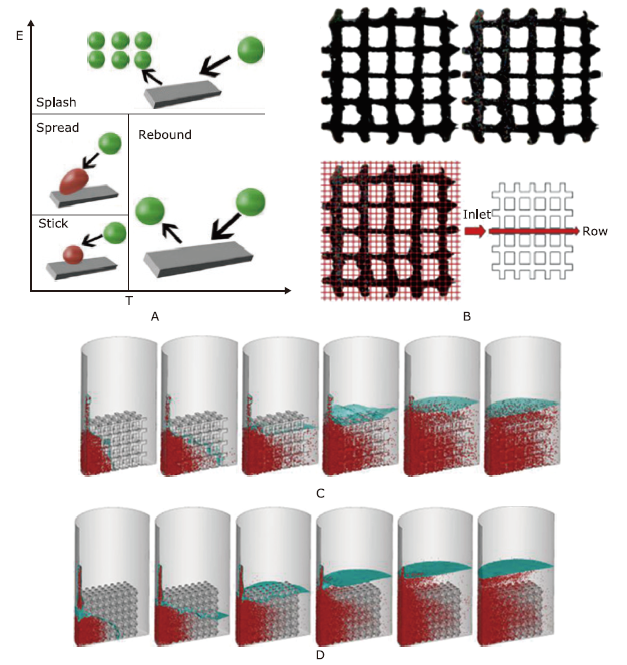

Xu S, Du P, Xie Y, et al. Cell distribution in a scaffold with random architectures under the influence of fluid dynamics. J Biomater Appl 2008; 23(3):229-45. doi: 10.1177/0885328207086322.

doi: 10.1177/0885328207086322

|

| 6. |

Olivares AL, Lacroix D. Simulation of cell seeding within a three-dimensional porous scaffold: a fluid-particle analysis. Tissue Eng Part C Methods 2012; 18(8):624-31. doi: 10.1089/ten.TEC.2011.0660.

doi: 10.1089/ten.TEC.2011.0660

|

| 7. |

Prendergast PJ, Huiskes R, Søballe K. ESB Research Award 1996. Biophysical stimuli on cells during tissue differentiation at implant interfaces. J Biomech 1997; 30(6):539-48. doi: 10.1016/s0021-9290(96)00140-6.

doi: 10.1016/s0021-9290(96)00140-6

pmid: 9165386

|

| 8. |

Byrne DP, Lacroix D, Planell JA, et al. Simulation of tissue differentiation in a scaffold as a function of porosity, Young’s modulus and dissolution rate: application of mechanobiological models in tissue engineering. Biomaterials 2007; 28(36):5544-54. doi: 10.1016/j.biomaterials.2007.09.003.

doi: 10.1016/j.biomaterials.2007.09.003

|

| 9. |

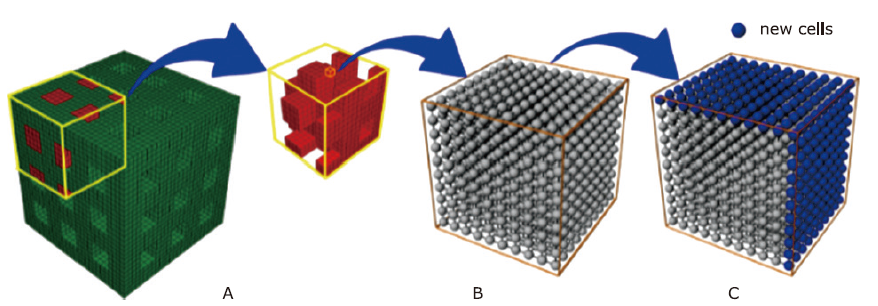

Liu Z, Tamaddon M, Chen SM, et al. Determination of an initial stage of the bone tissue ingrowth into titanium matrix by cell adhesion model. Front Bioeng Biotechnol 2021; 9:736063. doi: 10.3389/fbioe.2021.736063.

doi: 10.3389/fbioe.2021.736063

|

| 10. |

Liu J, Chen G, Xu H, et al. Pre-vascularization in fibrin Gel/PLGA microsphere scaffolds designed for bone regeneration. NPG Asia Materials 2018; 10(8):827-39. doi: 10.1038/s41427-018-0076-8.

doi: 10.1038/s41427-018-0076-8

|

| 11. |

Daley WP, Peters SB, Larsen M. Extracellular matrix dynamics in development and regenerative medicine. J Cell Sci 2008; 121(Pt 3):255-64. doi: 10.1242/jcs.006064.

doi: 10.1242/jcs.006064

|

| 12. |

Liu Z, Tamaddon M, Gu Y, et al. Cell seeding process experiment and simulation on three-dimensional polyhedron and cross-link design scaffolds. Front Bioeng Biotechnol 2020; 8:104. doi: 10.3389/fbioe.2020.00104.

doi: 10.3389/fbioe.2020.00104

|

| 13. |

Ali F, Taresh S, Al-Nuzaily M, et al. Stem cells differentiation and probing their therapeutic applications in hematological disorders: a critical review. Eur Rev Med Pharmacol Sci 2016; 20(20):4390-400. doi: 10.1155/2016/7653489.

doi: 10.1155/2016/7653489

|

| 14. |

Santoro R, Olivares AL, Brans G, et al. Bioreactor based engineering of large-scale human cartilage grafts for joint resurfacing. Biomaterials 2010; 31(34):8946-52. doi: 10.1016/j.biomaterials.2010.08.009.

doi: 10.1016/j.biomaterials.2010.08.009

|

| 15. |

Wendt D, Stroebel S, Jakob M, et al. Uniform tissues engineered by seeding and culturing cells in 3D scaffolds under perfusion at defined oxygen tensions. Biorheology 2006; 43(3, 4):481-8.

|

| 16. |

Cherry EM, JK Eaton. Shear thinning effects on blood flow in straight and curved tubes. Phys FLUIDS 2013; 25:0733104. doi: 10.1063/1.4816369.

doi: 10.1063/1.4816369

|

| 17. |

Reymond P, Perren F, Lazeyras F, et al. Patient-specific mean pressure drop in the systemic arterial tree, a comparison between 1-D and 3-D models. J Biomech 2012; 45(15):2499-505. doi: 10.1016/j.jbiomech.2012.07.020.

doi: 10.1016/j.jbiomech.2012.07.020

|

| 18. |

Truscello S, Kerckhofs G, Van Bael S, et al. Prediction of permeability of regular scaffolds for skeletal tissue engineering: a combined computational and experimental study. Acta Biomater 2012; 8(4):1648-58. doi: 10.1016/j.actbio.2011.12.021.

doi: 10.1016/j.actbio.2011.12.021

pmid: 22210520

|

| 19. |

Xiang J, Tremmel M, Kolega J, et al. Newtonian viscosity model could overestimate wall shear stress in intracranial aneurysm domes and underestimate rupture risk. J Neurointerv Surg 2012; 4(5):351-7. doi: 10.1136/neurintsurg-2011-010089.

doi: 10.1136/neurintsurg-2011-010089

|

| 20. |

Jiang Y, Zhang J, Zhao W. Effects of the inlet conditions and blood models on accurate prediction of hemodynamics in the stented coronary arteries. AIP Adv 2015; 5(5):057109. doi: 10.1063/1.4919937.

doi: 10.1063/1.4919937

|

| 21. |

Koch MA, Vrij EJ, Engel E, et al. Perfusion cell seeding on large porous PLA/calcium phosphate composite scaffolds in a perfusion bioreactor system under varying perfusion parameters. J Biomed Mater Res A 2010; 95(4):1011-8. doi: 10.1002/jbm.a.32927.

doi: 10.1002/jbm.a.32927

pmid: 20872752

|

| 22. |

Wendt D, Marsano A, Jakob M, et al. Oscillating perfusion of cell suspensions through three-dimensional scaffolds enhances cell seeding efficiency and uniformity. Biotechnol Bioeng 2003; 84(2):205-14. doi: 10.1002/bit.

doi: 10.1002/bit

pmid: 12966577

|

| 23. |

Stanton DW, CJ Rutland. Modeling fuel film formation and wall interaction in diesel engines. SAE Trans 1996; 808-24. doi: 10.4271/960628.

doi: 10.4271/960628

|

| 24. |

O’rourke PJ, Amsden AA. A particle numerical model for wall film dynamics in port-injected engines. SAE Technical Paper Series. Detroit: SAE; 1996. p.2000-13.

|

| 25. |

O’Rourke PJ, Amsden AA. A spray/wall interaction submodel for the KIVA-3 wall film model. SAE Technical Paper Series. Detroit: SAE; 2000. p.281-98. doi: 10.4271/2000-01-0271.

doi: 10.4271/2000-01-0271

|

| 26. |

Karande TS, Ong JL, Agrawal CM. Diffusion in musculoskeletal tissue engineering scaffolds: design issues related to porosity, permeability, architecture, and nutrient mixing. Ann Biomed Eng 2004; 32(12):1728-43. doi: 10.1007/s10439-004-7825-2.

doi: 10.1007/s10439-004-7825-2

pmid: 15675684

|

| 27. |

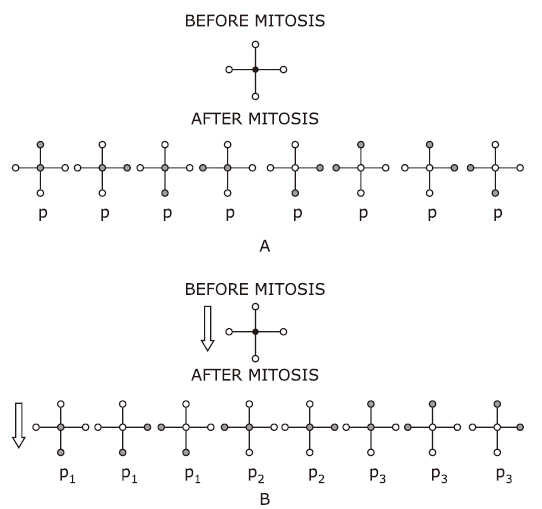

Makhaniok A, Haranava Y, Goranov V, et al. In silico prediction of the cell proliferation in porous scaffold using model of effective pore. Biosystems 2013; 114(3):227-37. doi: 10.1016/j.biosystems.2013. 10.001.

doi: 10.1016/j.biosystems.2013.10.001

pmid: 24141144

|

| 28. |

Dunn JC, Chan WY, Cristini V, et al. Analysis of cell growth in three-dimensional scaffolds. Tissue Eng 2006; 12(4):705-16. doi: 10.1089/ten.2006.12.705.

doi: 10.1089/ten.2006.12.705

|

| 29. |

Rouwkema J, Koopman B, Blitterswijk C, et al. Supply of nutrients to cells in engineered tissues. Biotechnol Genet Eng Rev 2010; 26:163-78. doi: 10.5661/bger-26-163.

doi: 10.5661/bger-26-163

pmid: 21415880

|

| 30. |

Reynolds M, McCann SR. Human marrow stromal cells in short-term semi-solid bone marrow culture in aplastic anaemia. Scand J Haematol 1985; 34(2):101-10. doi: 10.1111/j.1600-0609.1985.tb02241.x.

doi: 10.1111/j.1600-0609.1985.tb02241.x

pmid: 3975567

|

| 31. |

Winterton RHS. Thermal design of nuclear reactors. Elsevier; 1981. Available from: https://doi.org/10.1016/B978-0-08-024215-6.50003-6.

doi: https://doi.org/10.1016/B978-0-08-024215-6.50003-6

|

| 32. |

Botchwey EA, Dupree MA, Pollack SR, et al. Tissue engineered bone: measurement of nutrient transport in three-dimensional matrices. J Biomed Mater Res A 2003; 67(1):357-67. doi: 10.1002/jbm.a.10111.

doi: 10.1002/jbm.a.10111

pmid: 14517896

|

| 33. |

Mofrad AZ, Mashayekhan S, Bastani D. Simulation of the effects of oxygen carriers and scaffold geometry on oxygen distribution and cell growth in a channeled scaffold for engineering myocardium. Math Biosci 2017; 294:160-71. doi: 10.1016/j.mbs.2017.09.003.

doi: 10.1016/j.mbs.2017.09.003

|

| 34. |

Pérez MA, Prendergast PJ. Random-walk models of cell dispersal included in mechanobiological simulations of tissue differentiation. J Biomech 2007; 40(10):2244-53. doi: 10.1016/j.jbiomech.2006.10.020.

doi: 10.1016/j.jbiomech.2006.10.020

pmid: 17173925

|

| 35. |

Søballe K, Hansen ES, B-Rasmussen H, et al. Tissue ingrowth into titanium and hydroxyapatite-coated implants during stable and unstable mechanical conditions. J Orthop Res 1992; 10(2):285-99. doi: 10.1002/jor.1100100216.

doi: 10.1002/jor.1100100216

pmid: 1311039

|

| 36. |

Lanza R, Gearhart J, Hogan B, et al. Essentials of stem cell biology. Elsevier; 2009. Available from: https://doi.org/10.1016/C2009-0-00078-6.

doi: https://doi.org/10.1016/C2009-0-00078-6

|

),刘子钰1,2,3,*(

),刘子钰1,2,3,*( )

)

),Ziyu Liu1,2,3,*(

),Ziyu Liu1,2,3,*( )

)